Earthing Components

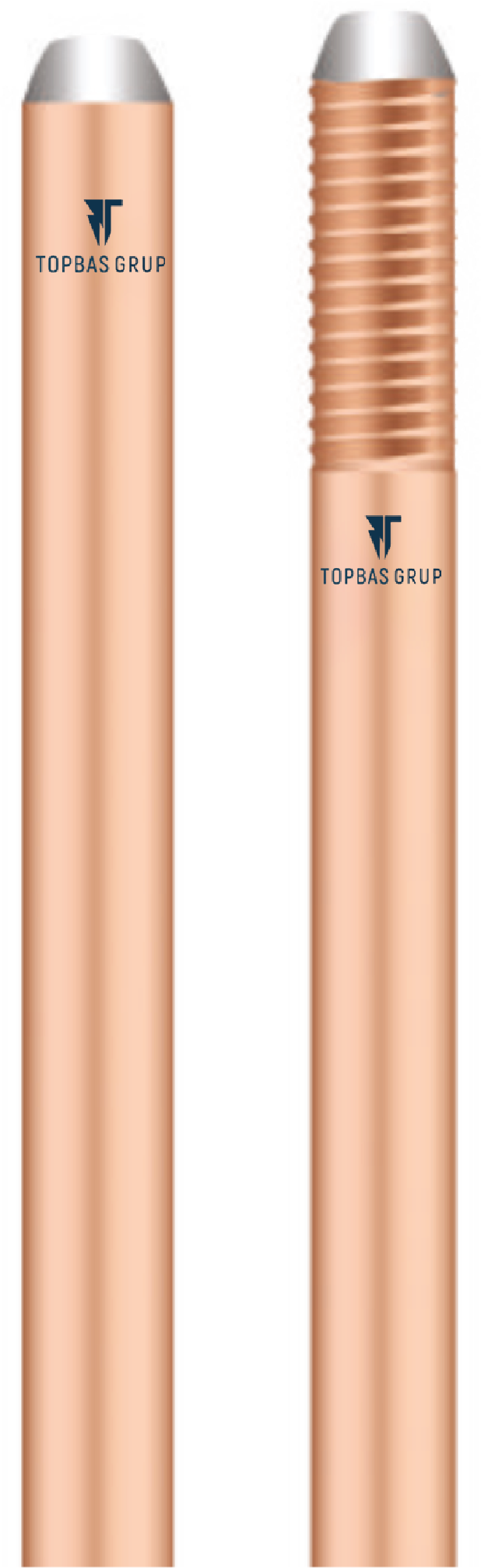

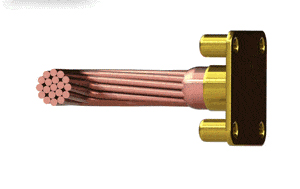

Copper Bonded Earth Rods

Copper Bonded Pipes

Galvanized Earth Rods

Carbolite Earthing Compound

Carbomaxx Earthing Compound

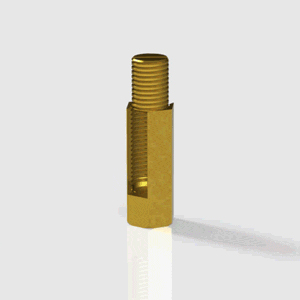

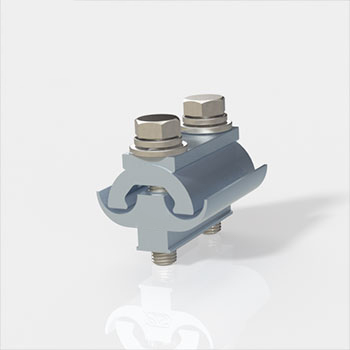

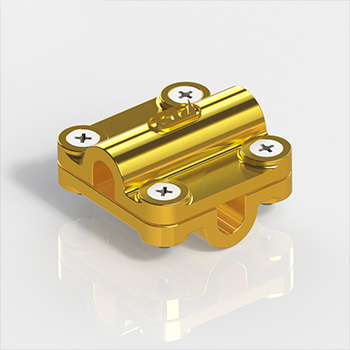

Grounding Accessories

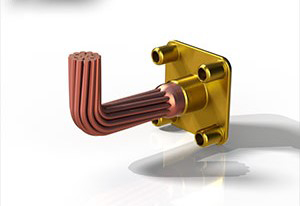

TopbasWeld

Exothermic Welding

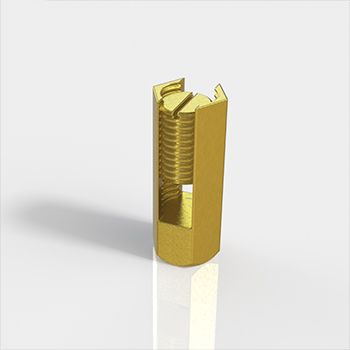

TopbasWeld Exothermic Welding is a simple, cost efficient, self-contained process of forming high quality permanent electrical connections. This process requires no external power or heat source making it completely portable. It uses a high temperature reaction of powdered copper oxide and aluminum, within a mold, to form permanent connections. In this process connections are made by pouring superheated molten copper alloy on and around the conductors to be joined. The reaction takes place very rapidly, therefore the total amount of heat applied to the conductors or surfaces is considerably less than that of brazing or soldering.

This is important in applications such as welding to insulated cables or thin wall pipes which might react to high heat. The process use aluminum particles as reducing agent with copper oxide to produce the chemical composition. Exothermic welding is a bonding of high conductivity high copper content alloy and high corrosion resistance.

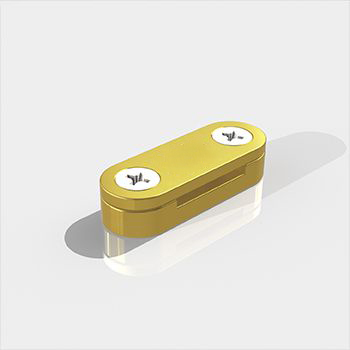

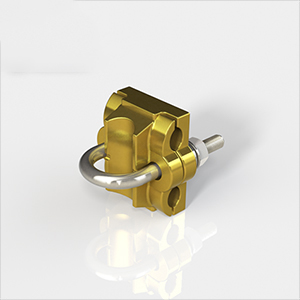

Welding Accessories

Mold Cleaning Brush

Cable Cleaning Brush

Flint Ignitor

Bus Bar Cleaning Brush

Mold Cleaners

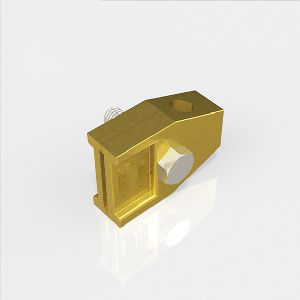

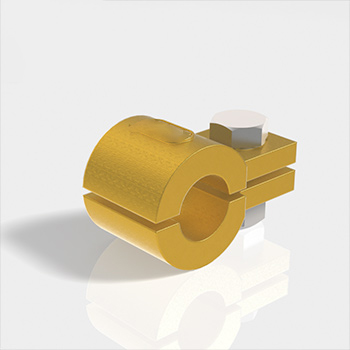

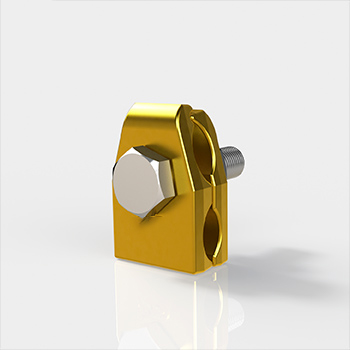

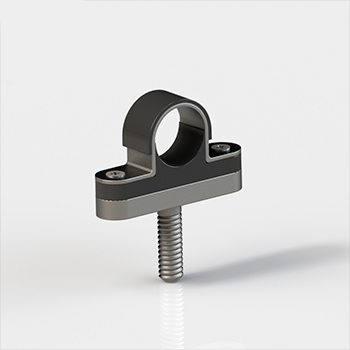

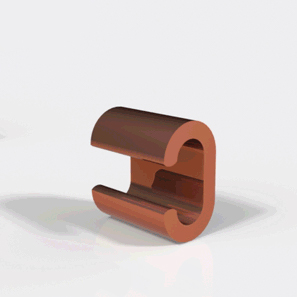

Handle Clamps

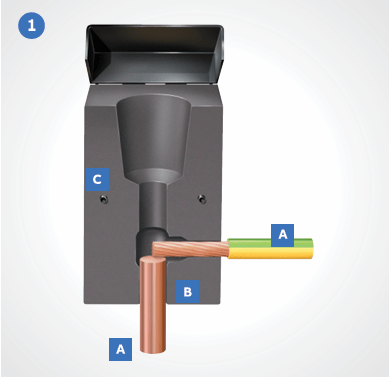

Operation steps

TopbasWeld EXOTHERMIC WELDING

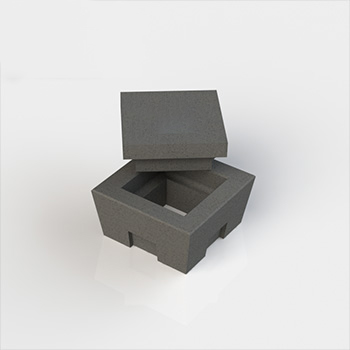

Locate the conductors (A)

to be joined in the weld cavity (B)

and close the mould (C).

Place the steel retaining disc in the

base of the crucible (D)

Pour in the weld powder (E)

followed by the starting powder (F).

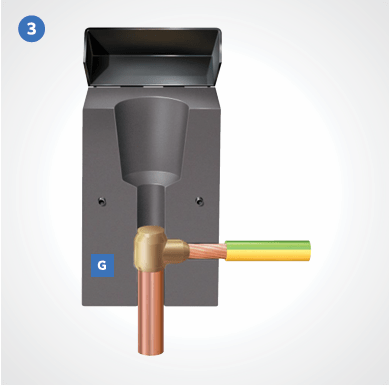

Ignite starting powder with a spark gun.

The resulting exothermic reaction reduces the weld powder to molten copper alloy which melts the retaining disc and flows into the weld cavity where it partially melts the conductors (G)

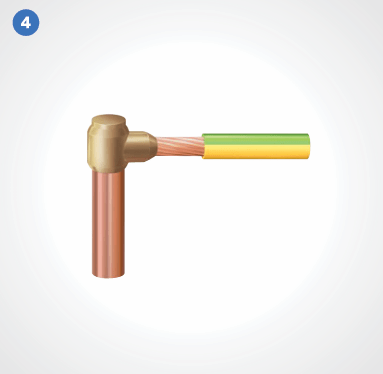

The molten copper alloy cools to leave a fusion weld of great mechanical and electrical integrity.